- Home

- CNC Turning Machining

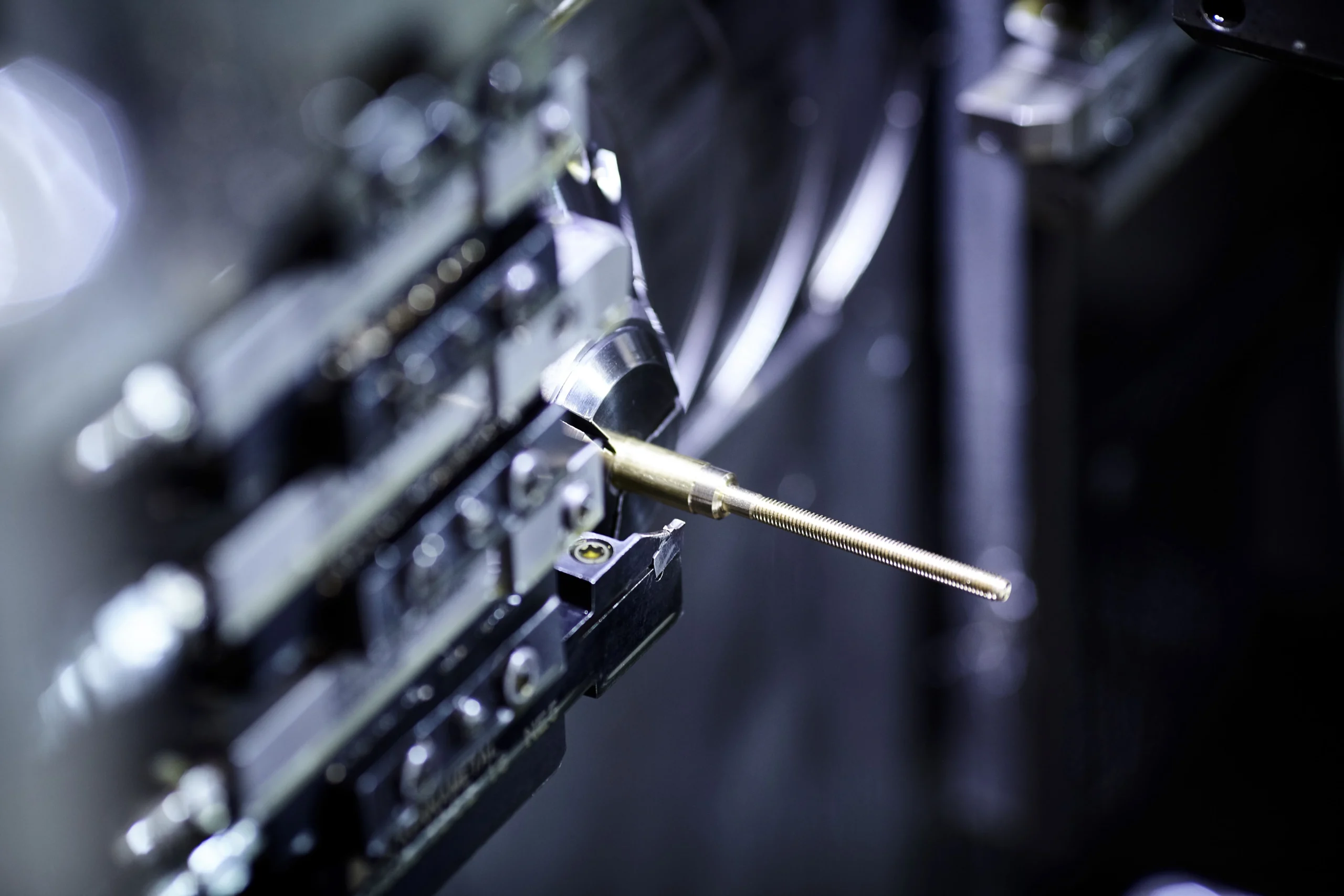

High-Quality CNC Turning Machining Services for Precision Turned Parts

CNC turning machining is a highly precise manufacturing process where a rotating workpiece—typically metal—is shaped using a cutting tool that moves longitudinally or radially to remove excess material. This advanced method is ideal for producing components such as shafts, bolts, and fasteners with exceptional accuracy and consistency.

At GM Precision, we specialize in CNC turning, leveraging state-of-the-art computer numerical control (CNC) machines to deliver precise, efficient, and high-quality results. Our expertise in CNC turning machining allows us to manufacture large quantities of identical parts rapidly while maintaining strict tolerances. Thanks to the flexibility of CNC lathes, we can easily adapt to different production requirements, ensuring customized solutions tailored to your specific needs.

By choosing GM Precision for your CNC turning machining needs, you benefit from superior quality, reliability, and efficiency, making us the trusted partner for precision-turned components across Quebec.

A CNC Turning Machining Workshop for Turned Parts Tailored to Your Needs

- Planning and Design - The first step involves using computer-aided design (CAD) to model the part to be machined (generating the necessary CNC programs for the machine tools).

- Material Selection - Mechanical properties, corrosion resistance, and durability are factors that influence material selection.

- Material Preparation - Once the material is chosen, it is prepared for machining (initial cutting or other treatments).

- Machine Setup - Before machining begins, it is essential to configure the software and machine parameters to automate and optimize operations.

- High-Performance Machining - Using high-performance machine tools allows for large-scale turning operations.

- Finishing and Assembly - After machining, parts made from various metals undergo finishing operations to ensure optimal surface quality.

- Quality Control - Quality Control A rigorous quality control process is in place to ensure that each part meets established quality standards.

- Packaging and Shipping - Finally, the machined parts are carefully packaged to protect them during transport. They are then shipped to customers, ready to be integrated into their applications.

Geneviève

MedicalNicolas

High technology industryJoffrey

Automotive performanceMartin

IndustrielTry us out.

Make an appointment with one of our precision machining experts.

Learn More about CNC Turning Machining

What is CNC turning ?

CNC turning machining is a manufacturing process that uses a lathe to remove material from a block of material to create cylindrical or complex-shaped parts. This process allows for achieving high precision tolerances.

What types of materials can be machined on a lathe?

A variety of materials can be machined on a lathe, including metals (steel, aluminum, brass), plastics, and certain composites. The choice of material depends on the properties required for the final part.

What are the advantages of CNC turning machining?

The main advantages of CNC turning machining include high precision, the ability to produce parts in series, a smooth surface finish, and versatility in terms of shapes and dimensions.

How does the CNC turning machining process work?

The process includes several steps: planning and design (CAD), material selection, material preparation, machine setup, machining, finishing, quality control, and finally packaging and shipping.

What are the production timelines for machined parts?

Production timelines vary depending on the complexity of the part and the quantity ordered. We are committed to meeting agreed-upon deadlines and informing our clients of any changes.

Do you offer design services?

Yes, we offer computer-aided design (CAD) services to assist our clients in modeling their parts before machining. This ensures that the parts meet the required specifications.

How do you ensure the quality of the machined parts?

We implement a rigorous quality control process throughout the machining process. Each part is inspected to verify that it meets the established tolerances and quality standards.

Do you accept custom orders?

Yes, we specialize in manufacturing custom parts. Whether for prototypes or mass production, we can tailor our services to meet your specific needs.

What are your production capabilities?

We have high-performance machine tools that allow us to produce at scale while maintaining high precision and quality.

How are the machined parts shipped?

Machined parts are carefully packaged to avoid damage during transport. We work with reliable carriers to ensure prompt and secure delivery to our clients.